Case Study: Fast Food Restaurant Grease Trap Interceptor

A fast food restaurant faced growing problems with the grease interceptor located in the facility. The grease trap needed to be pumped every 6 months and the effluent was exceeding discharge limits.

|

|

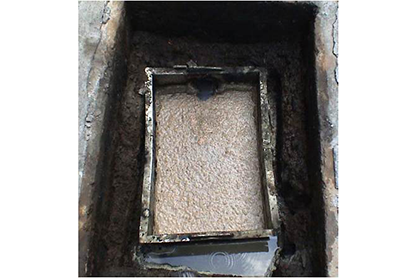

Thick with grease, cleaned every 6 months |

The management group elected to treat the problem with Orb-3 Wastewater Treatment Enzyme, and reported the following treatment results:

|

PARAMETERS |

13 November |

18 December |

|

| WTA04-1. BIOCHEMICAL OXYGEN DEMAND (BOD5), mg/L (By Azide Modification Dilution Technique) |

2579 |

850 |

700 |

| WTA05-1. CHEMICAL OXYGEN DEMAND (COD), mg/L (By Open Reflux) |

6320 |

1407 |

1400 |

| WTA24-1. pH VALUE at 24 C (By Glass Electrode) |

4.44 |

4.7 |

6.5 - 9.0 |

| WTA41-1. TOTAL SUSPENDED SOLIDS, mg/L (By Gravimetric, Drying to Constant Weight at 103 - 105 C) |

1500 |

147 |

980 |

| WTA23-1. OIL AND GREASE, mg/L (By Gravimetric - Petroleum Ether Extraction) |

203 |

12 |

70 |

A visual inspection of the treated contaminant also showed a marked difference over the 1-month period.

|

|

|

|

Effluent Sample Before Treatment |

Effluent Sample After Treatment |

Continued treatments with enzymes have reduced pumping requirements, put the restaurant back in line with discharge limits, tamed the foul odors, and restored the operation of the drain lines.